Ankoatr'izay, ny magnets SmCo dia manana endri-javatra hafa:

Fampisehoana azo itokisana: SmCo andriamby dia tena mahatohitra demagnetization mahatonga azy ireo azo itokisana amin'ny tontolo maro.

Ny fanoherana ny harafesina sy ny oxidation: Noho ny votoatin'ny vy ambany ao amin'ny fitaovana mitambatra, ny magnets SmCo dia manana fanoherana tsara amin'ny harafesina.Tsy toy ny NdFeB, SmCo andriamby tsy mila electroplating.

Fahamarinan'ny maripana: Ny SmCo dia afaka mitazona ny heriny andriamby amin'ny hafanana avo (249-300 ℃) ary ny mari-pana ambany dia ambany (-232 ℃).

Fitaovana marefo: Rehefa amin'ny sintering dia mety ho mora vaky ny akora, noho izy mora vaky sy mora vaky, misy fetra ny fanodinana, izay tsy azo atao ny fomba fanodinana nentim-paharazana.Na izany aza, dia mety ho tany, fa raha be dia be ny coolant ampiasaina.Izany dia satria ny coolant dia afaka manamaivana ny mety hisian'ny afo avy amin'ny tselatra mafana sy ny vovoka fikosoham-bary.

Fampiharana:

1. Motera PM avo lenta.Ny motera PM amin'ny ankapobeny dia mampiasa magnets ferrite na magnets NdFeB.Fa any amin'ny toerana izay mihoatra ny 200 ℃ ny mari-pana na ny torque stall lehibe, SmCo PM ihany no môtô.

2. Fitaovana elektrika amin'ny rafitra fanamafisam-peo avo lenta.

3. Rafitra fitaovana azo antoka indrindra.Ny fitaovana maro ampiasaina amin'ny aerospace, ny fiaramanidina, ny fitsaboana ary ny sehatra hafa dia tsy maintsy mampiasa andriamby maharitra SmCo mba hiantohana ny fahamendrehana sy ny fiarovana tonga lafatra.

4. Ao amin'ny radara sy ny rafitra fifandraisana tena manan-danja, be dia be ny onjam-peo fantsona, magnetrons, manenjika fantsona, manenjika onja fantsona, gyrotrons ary fitaovana elektrika banga hafa no ampiasaina, ary ny SmCo andriamby manao elektrôna taratra manaraka ny fihetsehana amin'ny lalana voatondro.

5. SmCo andriamby extractors ao amin'ny lavaka lalina ambanin'ny 3000 metatra, ary SmCo andriamby drive (paompy) amin'ny mari-pana ambony ny 200 ℃.

6. Lohan'ny suction andriamby, separator andriamby, mitondra andriamby, NMR, sns.

Lisitry ny kilasy SmCo Magnet

| KEVITRA | No | Br | Hcb | Hcj | (BH) max | TC | TW | (Br) | Hcj | ||||

| T | |Mp | KA/m | KOe | KA/m | KOe | KJ/m3 | MGOe | ℃ | ℃ | %℃ | %℃ | ||

| 1:5 SmCo5 (Smpr)Co5 | YX-16 | 0.81-0.85 | 8.1-8.5 | 620-660 | 7.8-8.3 | 1194-1830 | 15-23 | 110-127 | 14-16 | 750 | 250 | -0,050 | -0.30 |

| YX-18 | 0.85-0.90 | 8.5-9.0 | 660-700 | 8.3-88 | 1194-1830 | 15-23 | 127-143 | 16-18 | 750 | 250 | -0,050 | -0.30 | |

| YX-20 | 0.90-0.d4 | 9.0-9.4 | 676-725 | 8.5-9.1 | 1194-1830 | 15-23 | 150-167 | 19-21 | 750 | 250 | -0,050 | -0.30 | |

| YX-22 | 0.92-0.96 | 9.2-9.6 | 710-748 | 8.9-94 | 1194-1830 | 15-23 | 160-175 | 20-22 | 750 | 250 | -0,050 | -0.30 | |

| YX-24 | 0.96-1.00 | 9.6-10.0 | 730-770 | 9.2-9.7 | 1194-1830 | 15-23 | 175-190 | 22-24 | 750 | 250 | -0,050 | -0.30 | |

| 1:5 SmCo5 | YX-16S | 0.79-0.84 | 7.9-8.4 | 612-660 | 7.7-83 | ≥ 1830 | ≥ 23 | 118-135 | 15-17 | 750 | 250 | -0.035 | -0.28 |

| YX-18S | 0.84-0.89 | 8.4-89 | 644-692 | 8.1-8.7 | ≥ 1830 | ≥ 23 | 135-151 | 17-19 | 750 | 250 | -0,040 | -0.28 | |

| YX-20S | 0.89-0.93 | 8.9-9.3 | 684-732 | 8.6-92 | ≥ 1830 | ≥ 23 | 150-167 | 19-21 | 750 | 250 | -0.045 | -0.28 | |

| YX-22S | 0.92-0.96 | 9.2-9.6 | 710-756 | 8.9-95 | ≥ 1830 | ≥ 23 | 167-183 | 21-23 | 750 | 250 | -0.045 | -0.28 | |

| YX-24S | 0.96-1.00 | 9.6-10.0 | 740-788 | 9.3-9.9 | ≥ 1830 | ≥ 23 | 183-199 | 23-25 | 750 | 250 | -0.045 | -0.28 | |

| 1:5 (SmGd)Co5 | LTc(YX-10) | 0.62-0.66 | 62-6.6 | 485-517 | 6.1-6.5 | ≥ 1830 | ≥ 23 | 75-8A | 9.5-11 | 750 | 300 | 20-100 ℃ + 0,0156% ℃ 100-200 ℃ + 0,0087 % ℃ 200-300 ℃ + 0,0007 % ℃ | |

| Ce(CoFeCu)5 | YX-12 | 0.7Q-0.74 | 7.0-7.4 | 358-390 | 4.5-4.9 | 358-478 | 4.5-6 | 80-103 | 10-13 | 450 | 200 | ||

| Sm2 (CoFeCuZr)17 | YXG-24H | 0.95-1.02 | 9.5-10.2 | 692-764 | 8.7-9.6 | ≥ 1990 | ≥ 25 | 175-191 | 22-24 | 800 | 350 | -0,025 | -0.20 |

| YXG-26H | 1.02-1.05 | 10.2-10.5 | 748-796 | 9.4-10.0 | ≥ 1990 | ≥ 25 | 191-207 | 24-26 | 800 | 350 | -0.030 | -0.20 | |

| YXG-28H | 1.03-1.08 | 10.3-10.8 | 756-812 | 9.5-10.2 | ≥ 1990 | ≥ 25 | 207-220 | 26-28 | 800 | 350 | -0.035 | -0.20 | |

| YXG-30H | 1.08-1.10 | 10.8-11.0 | 788-835 | 9.9-10.5 | ≥ 1990 | ≥ 25 | 220-240 | 28-30 | 800 | 350 | -0.035 | -0.20 | |

| YXG-32H | 1.10-1.13 | 11.0-11.3 | 812-860 | 10.2-10.8 | ≥ 1990 | ≥ 25 | 230-255 | 29-32 | 800 | 350 | -0.035 | -0.20 | |

| YXG-22 | 0.93-0.97 | 9.3-97 | 676-740 | 8.5-93 | ≥ 1453 | ≥ 18 | 160-183 | 20-23 | 800 | 300 | -0.020 | -0.20 | |

| YXG-24 | 0.95-1.02 | 9.5-10.2 | 692-764 | 87-9.6 | ≥ 1433 | ≥ 18 | 175-191 | 22-24 | 800 | 300 | -0,025 | -0.20 | |

| YXG-26 | 1.02-1.05 | 10.2-10.5 | 748-796 | 9.4-10.0 | ≥ 1433 | ≥ 18 | 191-207 | 24-26 | 800 | 300 | -0.030 | -0.20 | |

| YXG-28 | 1.03-1.08 | 10.3-10.8 | 756-812 | 9.5-10.2 | ≥ 1433 | ≥ 18 | 207-220 | 26-28 | 800 | 300 | -0.035 | -0.20 | |

| YXG-30 | 1.08-1.10 | 10.8-11.0 | 788-835 | 9.9-10.5 | ≥ 1453 | ≥ 18 | 220-240 | 28-30 | 800 | 300 | -0.035 | -0.20 | |

| YXG-32 | 1.10-1.13 | 11.0-11.3 | 812-860 | 10.2-10.8 | ≥ 1433 | ≥ 18 | 230-255 | 29-32 | 800 | 300 | -0.035 | -0.20 | |

| YXG-26M | 1.02-1.05 | 10.2-10.5 | 676-780 | 8.5-9.8 | 955-1433 | 12-18 | 191-207 | 24-26 | 800 | 300 | -0.035 | -0.20 | |

| YXG-28M | 1.03-1.08 | 10.3-10.8 | 676-796 | 8.5-10.0 | 955-1433 | 12-18 | 207-220 | 26-28 | 800 | 300 | -0.035 | -0.20 | |

| YXG-30M | 1.08-1.10 | 10.8-11.0 | 676-835 | 8.5-10.5 | 955-1433 | 12-18 | 220-240 | 28-30 | 800 | 300 | -0.035 | -0.20 | |

| YXG-32M | 1.10-1.13 | 11.0-11.3 | 676-852 | 8.5-10.7 | 955-1433 | 12-18 | 230-255 | 29-32 | 800 | 300 | -0.035 | -0.20 | |

| YXG-24L | 0.95-1.02 | 9.5-10.2 | 541-716 | 6.8-9.0 | 636-955 | 8-12 | 175-191 | 22-24 | 800 | 250 | -0,025 | -0.20 | |

| YXG-26L | 1.02-1.05 | 10.2-10.5 | 541-748 | 6.8-9.4 | 636-955 | 8-12 | 191-207 | 24-26 | 800 | 250 | -0.035 | -0.20 | |

| YXG-28L | 1.03-1.08 | 10.3-10.8 | 541-764 | 6.8-9.6 | 636-955 | 8-12 | 207-220 | 26-28 | 800 | 250 | -0.035 | -0.20 | |

| YXG-30L | 1.08-1.15 | 10.8-11.5 | 541-796 | 6.8-10.0 | 636-955 | 8-12 | 220-240 | 28-30 | 800 | 250 | -0.035 | -0.20 | |

| YXG-32L | 1.10-1.15 | 11.0-11.5 | 541-812 | 6.8-10.2 | 636-955 | 8-12 | 230-255 | 29-32 | 800 | 250 | -0.035 | -0.20 | |

| (SmEr)2(CoTM)17 | LTC (YXG-22) | 0.94-0.98 | 9.4-9.8 | 668-716 | 8.4-9.0 | ≥1433 | ≥18 | 167-183 | 21-23 | 840 | 300 | -50-25 ℃ + 0,005% ℃ 20-100 ℃ -0,008% ℃ 100-200 ℃ -0,008% ℃ 200-300 ℃ -0,011 % ℃ | |

| Ny toetra ara-batana ny Samarium Cobalt | ||

| fikirana | SmKo 1:5 | SmKo 2:17 |

| Curie mari-pana (℃) | 750 | 800 |

| Maximum miasa mari-pana (℃ | 250 | 300 |

| Hv(MPa) | 450-500 | 550-600 |

| Hateza (g/cm³) | 8.3 | 8.4 |

| Temperature coefficient ny Br(%/℃) | -0.05 | -0.035 |

| Temperature coefficient ny iHc(%/℃) | -0.3 | -0.2 |

| Henjana (N/mm) | 400 | 350 |

| Herin'ny fahatapahan'ny transverse (N/mm) | 150-180 | 130-150 |

Fampiharana

SmCo andriamby dia be mpampiasa amin'ny aerospace, mari-pana ambony maotera, microwave fitaovana, fifandraisana, fitsaboana, fitaovana sy ny metatra, isan-karazany andriamby fifindran'ny fitaovana, sensor, andriamby processeur, feo coil Motors sy ny sisa.

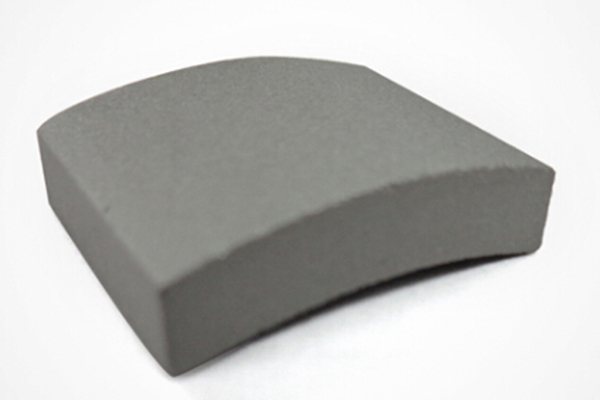

Fampisehoana sary

-

Segment NdFeB, matetika ampiasaina amin'ny herinaratra ...

-

Round NdFeb, amin'ny ankapobeny ampiharina amin'ny electroacou...

-

Habe samihafa amin'ny andriamby fingotra / takelaka andriamby

-

Endriny hafa NdFeB, toy ny bikan'ny mofo, lavaka-s...

-

Ring NdFeB, matetika ampiasaina amin'ny fanamafisam-peo

-

Magnet Assemblies miaraka amin'ny NdFeB, SmCo, AlNiCo ary ...